Wiring High Current Configurations for Diesel Fuel Pump Applications

This article focuses on the proper wiring of diesel fuel pumps. While FUELAB pumps are efficient, they can draw much electrical current during high flow/high pressure use. This article will concentrate on wiring pumps for reliable and safe use while operating under these conditions. While people tend to focus on the performance characteristics of high performance diesel fuel pumps, they often don’t give as much consideration to its proper wiring. This can be a critical mistake as without a reliable source of power the pump is useless. Poor wiring techniques can not only dramatically reduce the reliability and capability of the fuel pump, but can contribute to fire as well. To help minimize problems encountered during any product installation it is essential to follow the provided instructions. Included instructions not only help avoid mistakes, but also provide valuable specifications and requirements that help ensure component compatibility. Therefore, carefully following FUELAB installation instructions included with each pump is imperative. As an expansion on these instructions, this article focuses on additional requirements for use of FUELAB pumps operating at maximum potential, and addresses increased current draw, vibration, abrasion, and general safety.

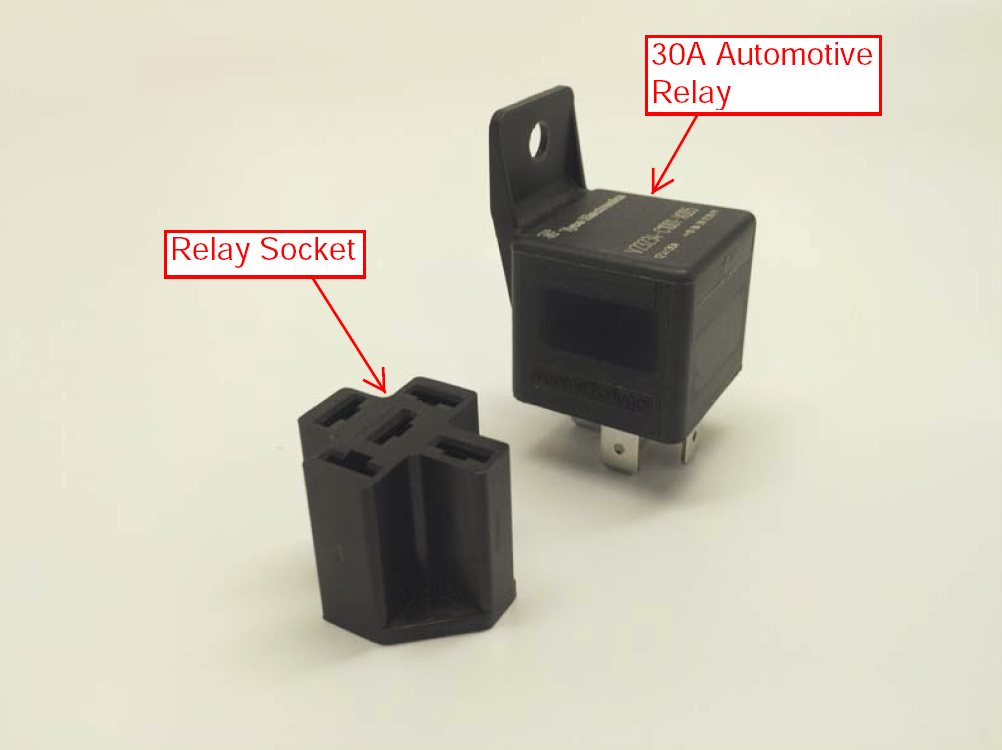

Increased Current Draw Focus: Relays For the bulk of the FUELAB Diesel Line that is relatively low pressure, installation does not require a relay. While the 200 GPH lift pumps using our installation kit can support much power, the system is still designed to operate at the "Reduced Speed" mode of operation only. However, for very high flow applications (typically used in conjunction of modified fuel tank or fuel cell) a relay will be required due to the increased demand for current draw. Inside a relay is a small coil of wire that creates a magnetic field high enough to actuate a power switch inside the coil. When the small amount of current passes through the coil (trigger), the relay activates a high current capacity circuit. This gives the ability to not only switch high amounts of current, but to do so remotely – therefore eliminating the need to wire thick gauge wire all of the way to the switch.

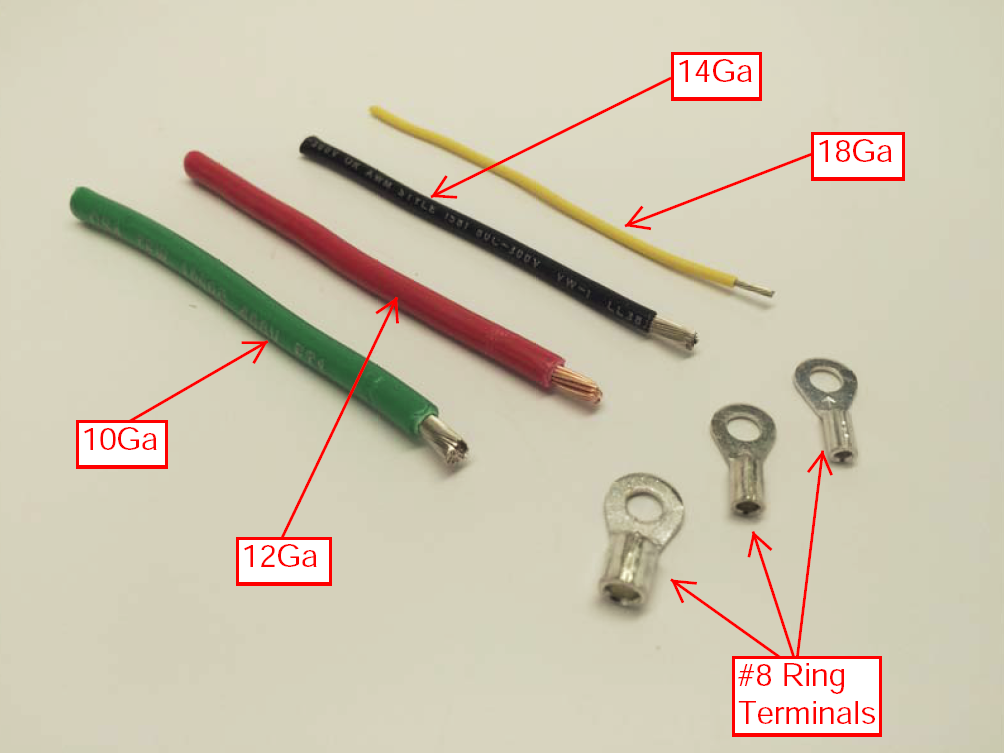

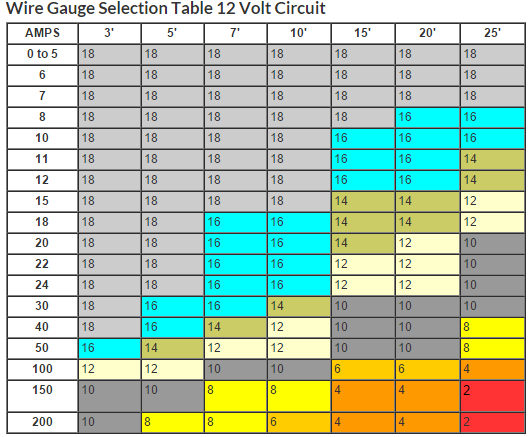

Focus: Wire Gauge In general, Fuelab recommends 10 or 12 gauge wiring. Depending on the length of wire, and the operating condition and model of pump, 12 gauge is usually sufficient for all 200 GPH pumps. If extremely long wiring is required use of 10 gauge wire is recommended.

The following chart can be used to determine the appropriate wire gauge for your application.

Focus: Additional Power Draw Considerations Other high power capacity automotive systems should be considered when planning an automotive electrical system. In addition to high flow fuel pumps, such components as high energy ignition systems, high powered lights, and audio amplifiers can significantly increase electrical load. In these cases the power supply components, such as battery terminal connectors, may need to be upgraded. Component suppliers with these types of solutions include Crutchfield: http://www.crutchfield.com/.

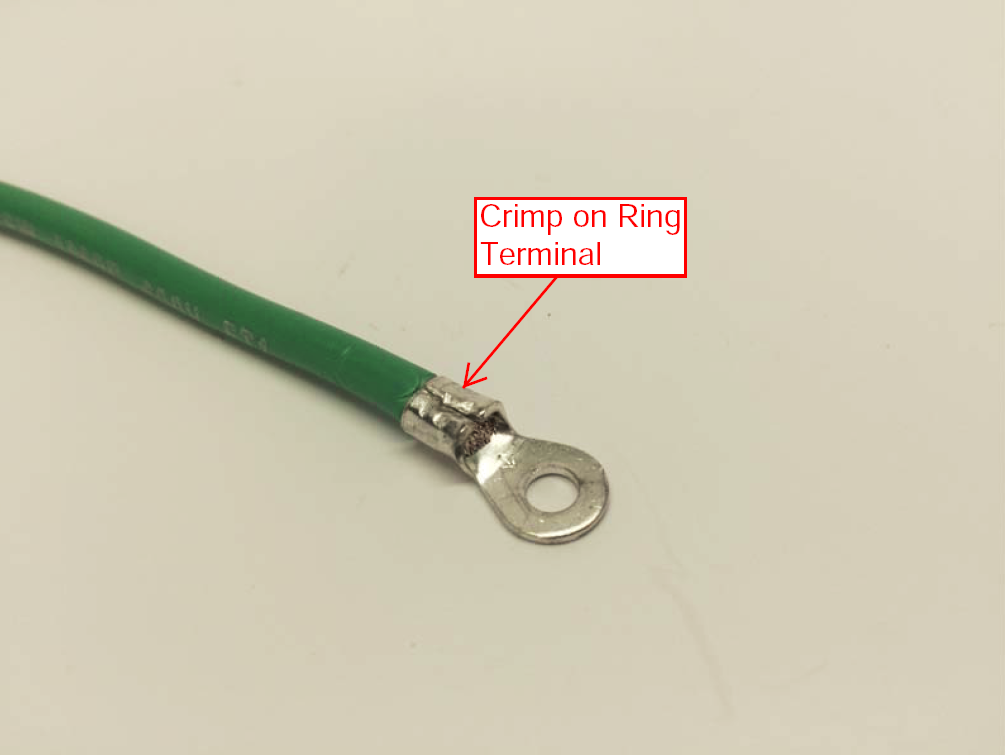

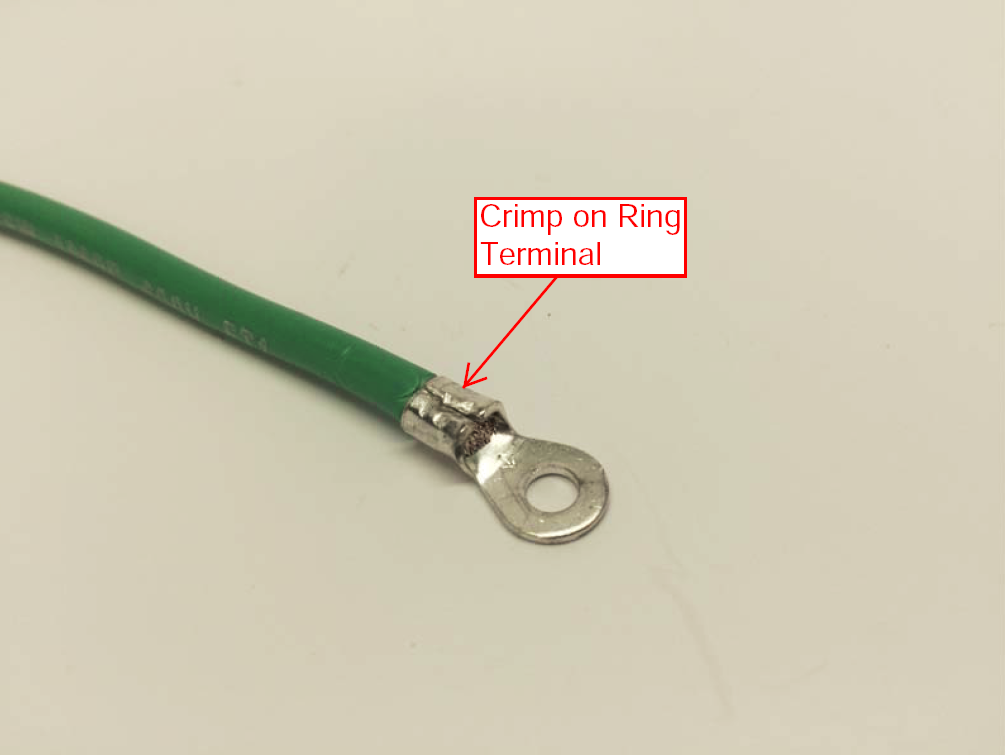

Vibration Focus: Wire Crimping Many opinions exist about crimping and not crimping connectors. As a general rule it’s best to only crimp the wiring to connectors. While soldering can help reduce the amount of voltage drop at the connector in some high vibration conditions, a soldered (even crimped and soldered) attachment can break at the connector due to wire flex.

Abrasion Focus: Wire Wrap Wire wrap around the harness can help prevent abrasion of the vehicle's body against the wire insulation – thereby avoiding an electrical short. Wrap can also make for a "clean" installation as well as help conceal vehicle modifications. Use of loop clamps to secure the harness is helpful in reducing vibration to connectors, and positioning the harness in a desired location on the vehicle's body.

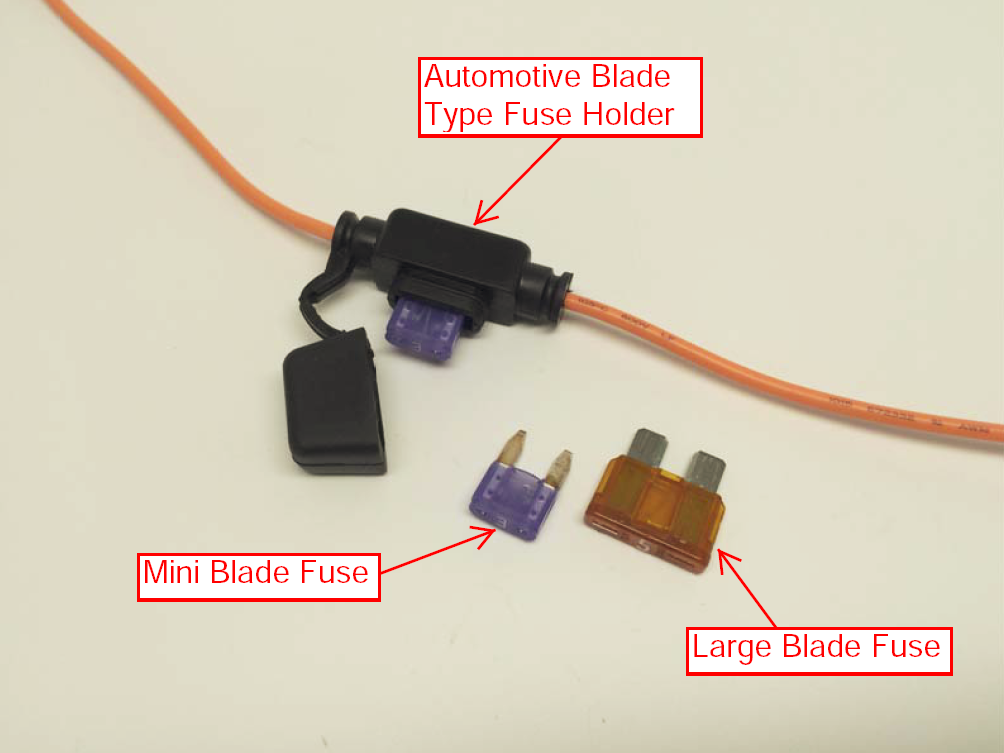

Safety Focus: Fuses Keeping the fuse close to the battery is helpful for safety in case of an accident. However, do not locate the fuse on top of the battery as the fuse could be a potential ignition source at the battery.

Wire & Connector Sources Many sources of electrical products exist. For your reference - specialty electrical supply companies specific to the automotive aftermarket include: Painless Performance Products: http://www.painlessperformance.com/ Ron Francis Wiring: https://www.ronfrancis.com/ WiringProducts.com: http://www.wiringproducts.com/

You must login to post comments.