Fuel Line Size vs. Pressure Drop

It is important to understand the relationship between fuel line size and fuel pressure when planning a fuel delivery system. Fuel systems can be incorrectly designed if the pressure loss attributed to the length of the fuel lines isn’t taken into account.

Excessive pressure drop in the fuel lines feeding a carburetor or EFI system will inhibit their proper function, and in the case of a bypass or return style regulator, excessive pressure drop through a return line will squelch the regulator's ability to operate correctly.

To deliver fuel at the correct flow rate and pressure, careful consideration of fuel line diameter and length, as well as whether the application is carbureted or EFI, is very important. Back in the early days of aftermarket EFI systems, the great veterans of carbureted fuel delivery systems would scoff at running a small EFI return fuel line saying "It will never work!" They would also look at the much smaller return orifice in the EFI regulator and say "It will not flow enough!" What they did not know was that Carbureted and EFI systems operate differently because of sensitivity to pressure drop.

The topic of determining actual pressure drop and how it can affect different systems is typically not addressed or performed. We often apply the "what has worked" principle and have a general idea about what line size can work and what will be too restrictive. This article examines an analysis of pressure drop for a supply line used in a fuel system. The example uses experimentally derived data to show how pressure drop in the fuel line will have performance effects on the fuel system. This examination will also show how this performance loss affects a low pressure carbureted pump versus an EFI pump.

While this article does not show an analysis over an entire fuel system, it does discuss how much pressure drop exists in some typical fuel lines, how can this information can be used to see how performance is affected, and how some components behave differently than others.

Let’s start by examining the source of pressure loss: Friction. Fluids experience friction as they pass through pipes and hoses, and this drag reduces the pressure under which the fluid is being delivered. In the case of fuel lines, two influences increase friction and therefore fuel pressure drop. The first is the length of the fuel line – the longer it is the more friction will be incurred. The second is flow rate – as the rate is increased so is friction.

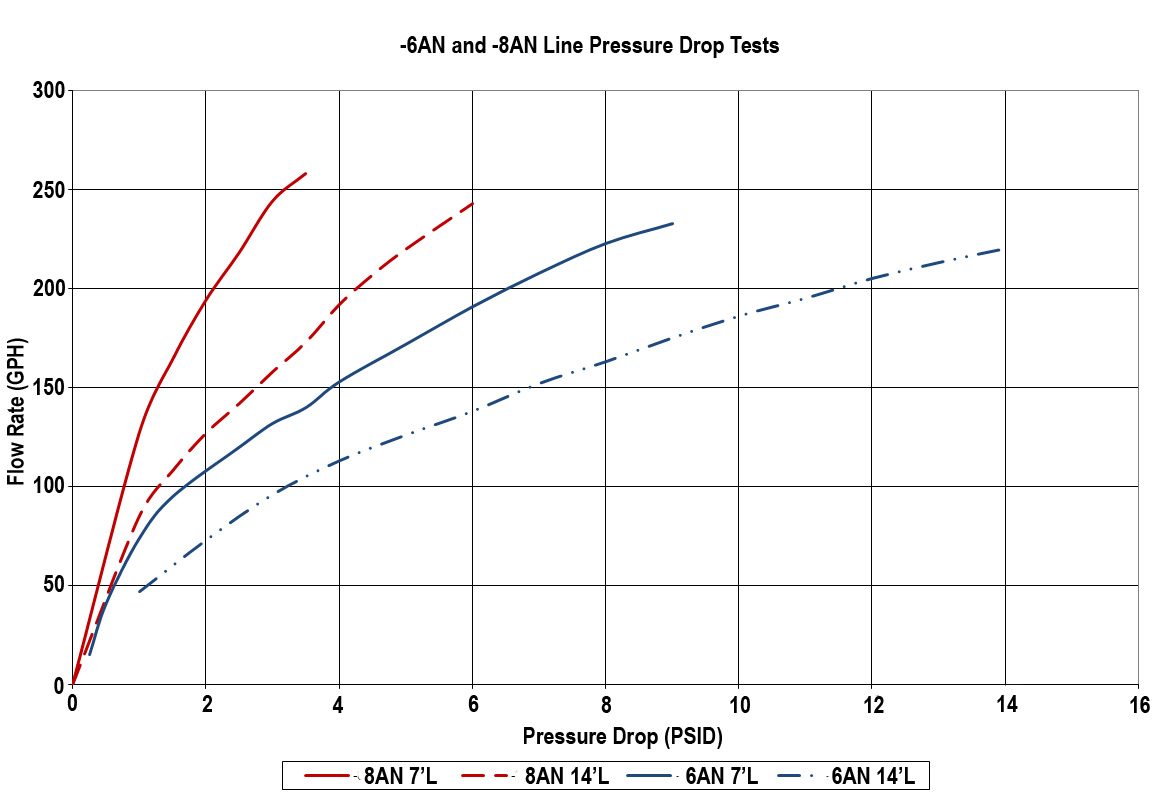

Graph A shows the relationship between measured pressure drop as a function of flow rate, for four different fuel lines (two different sizes at two different lengths).

Every fuel line experiences pressure loss depending on fuel line length, and fuel flow rate. It should be noted that fuel lines which feed pressure gauges experience the least amount of loss, as the flow rate through the gauge line plummets to near zero flow levels. This is why gauges typically use 3/16" or 1/4" line size, as they will not affect performance due to pressure loss. Now, we’ll examine how fuel flow rate is affected by fuel pressure drop in a carbureted system. Let’s take the maximum flow rate variable into consideration. Let’s say we are dealing with a carbureted fuel pump that has the following flow rate/outlet pressure characteristics:

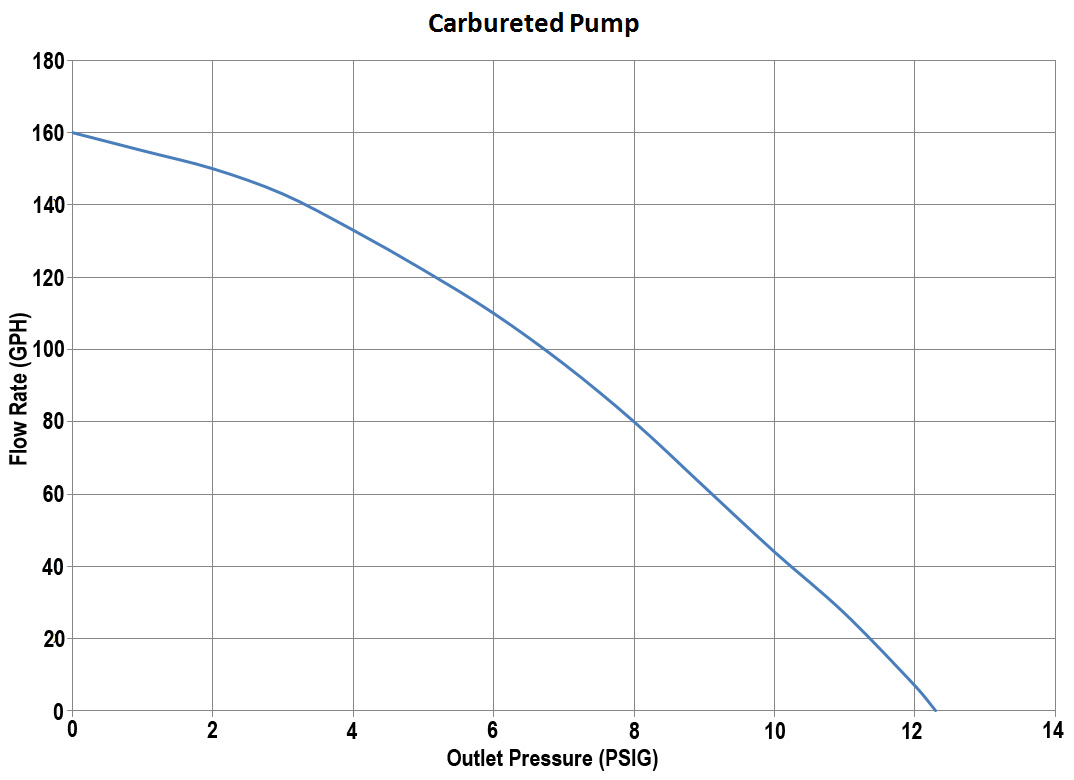

Graph B shows the pump’s maximum possible flow rate is at free-flow (160 GPH), yet we know the maximum flow rate while under actual operation is going to be much less. If the minimum required fuel system pressure for our example is 6 PSI (not accounting for other losses), the graph shows us the maximum flow rate to be considered is 110 GPH.

Taking this information into consideration, let’s examine how different fuel line sizes can affect pressure drop. This example compares -6AN and -8AN supply fuel lines, both are 14' long. Referring to Graph A - the amount of pressure drop we can expect for 14' fuel lines at 110 GPH is:

- -6AN Fuel Line: nearly 4 PSID

- -8AN Fuel Line: nearly 1.5 PSID

It seems that a "couple of PSI" will not change much. However, depending on how much pressure loss can be tolerated by the system before it affects performance, it could prove to be a significant problem.

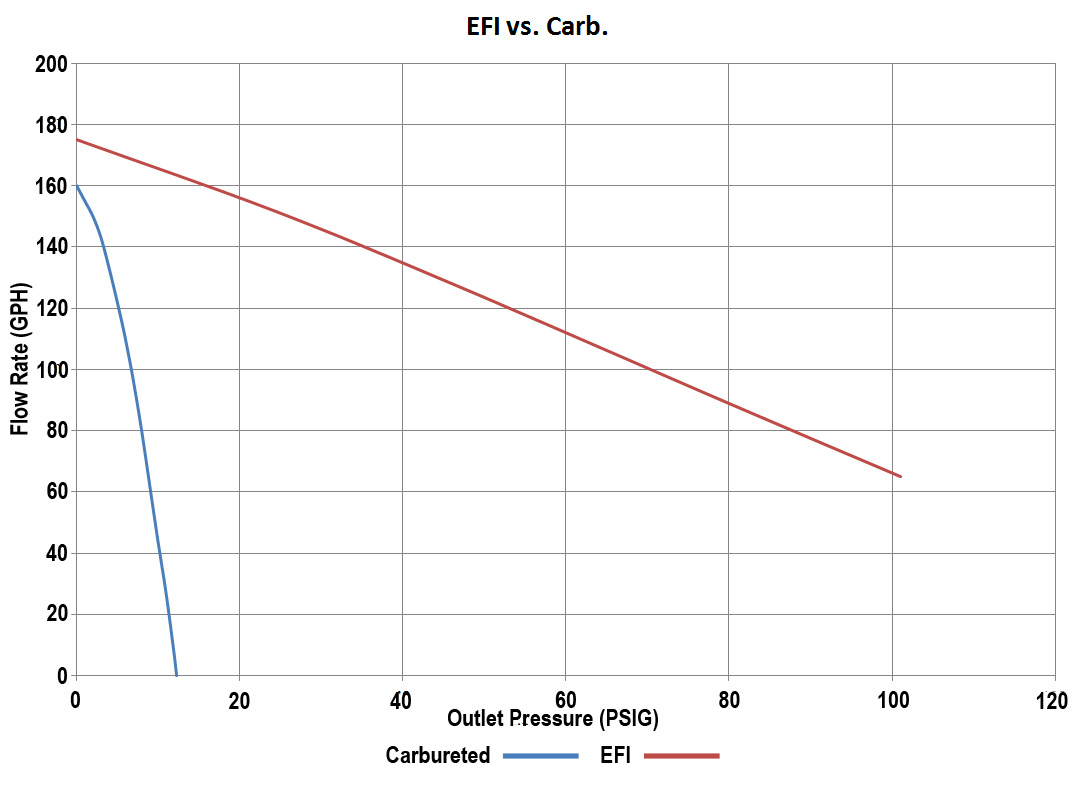

Graph B shows that by adding just two PSI of line drop to this example pump, we can lower the available flow rate from 110 GPH to 80 GPH (over a fourth of the total capacity). This example shows carbureted systems are very sensitive to fuel line size. However, it is important to know that things are a bit different when determining the appropriate fuel line size for an EFI vehicle. EFI fuel pumps don’t experience the same pressure loss issues as carburetor fuel pumps. Take a look at Graph C which describes an example of the performance of an EFI fuel pump versus a carbureted fuel pump.

Graph C shows the fuel flow rate for the carbureted pump is much lower than that of the EFI pump when at higher pressure.

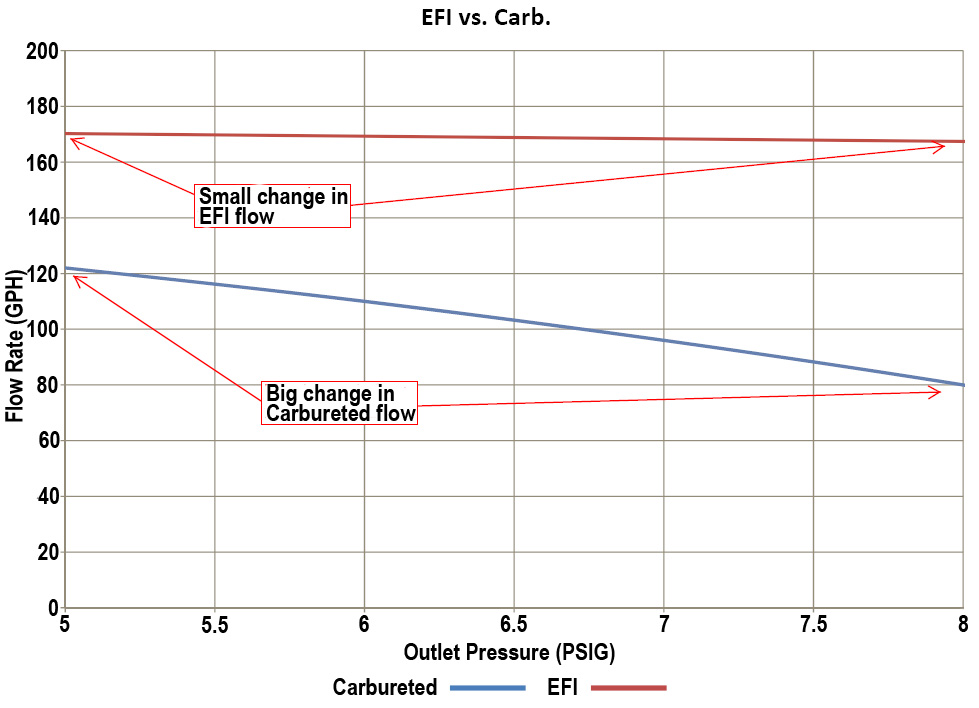

So, let's examine Graph D that compares the performance over a span of 3 PSI, near the lower end of the pressure range.

Graph D

When we take a closer look, we can see that the two curves have different slopes. Compared to the carbureted fuel pump, the graph for EFI fuel pump seems to be nearly strait across. If we add 3 PSI in difference regarding pressure, the EFI pump flow rate performance may have dropped off less than 3%, yet the carbureted pump flow rate loss is much more dramatic at greater than 33%. Showing EFI systems are not nearly as sensitive to fuel line size as carbureted systems. These examples go to show that when planning a fuel system not only is flow rate and line length important when determining fuel line size, but more importantly: Whether the fuel delivery system is carburetor or EFI based.

You must login to post comments.